Early Origins of Tandon Group’s Manufacturing Excellence

Before fledging Tandon Magnetics could gain prominence as an exporter of key components IBM would incorporate into their pioneering floppy disk drives, founder M.L. (Manny) Tandon was faced with two significant challenges. The first early problem was sustaining a stable, dedicated workforce.

During the mid-1970s, entry-level assembly workers, males in particular, among India’s handful of electronics manufacturers were quick to hop from town to city in search of other career options. After noticing the costs associated with the high turnover, namely constant training of replacements, were gnawing at his bottom line, Manny turned to what at that time was considered a radical solution–avoiding hiring men in favor of a mostly female workforce.

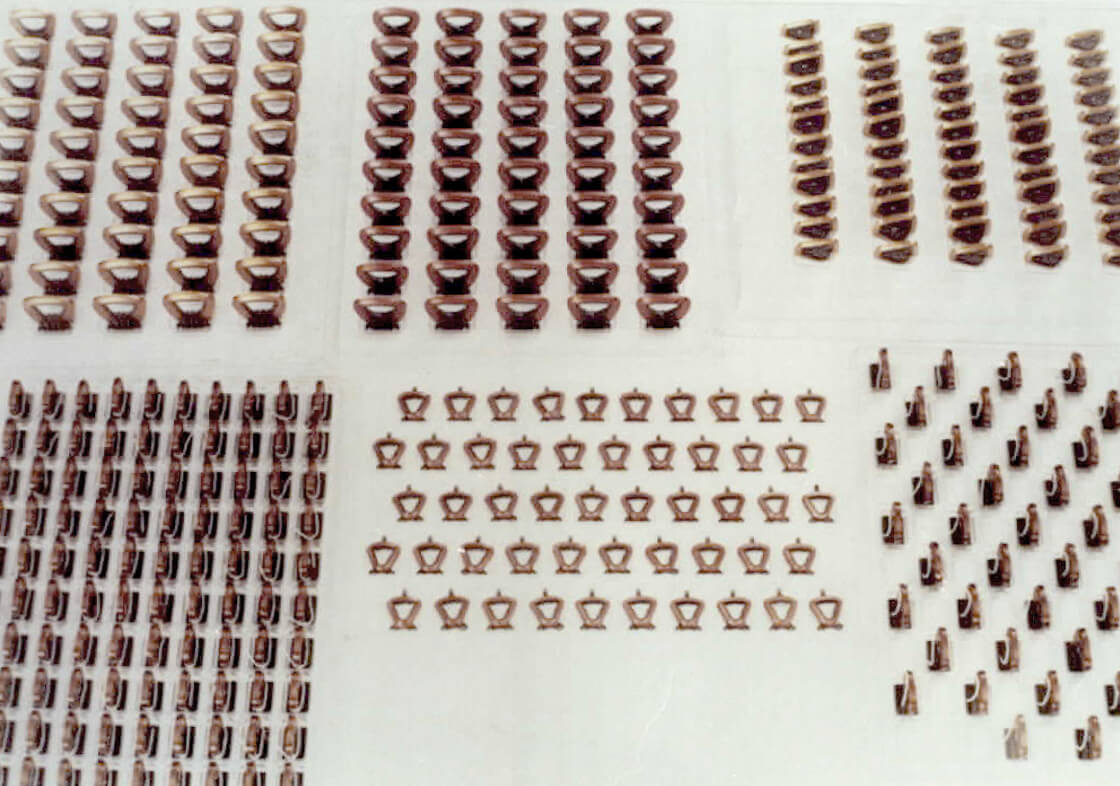

Indian culture frowned upon young unmarried women leaving their households–or even independently taking nearby jobs on their own. But Manny recognized an opportunity to capitalize upon an untapped pool of industrial talent. Besides delivering a strong work ethic and long–term company loyalty, the all-female production floor proved to offer another distinct advantage–superior manual dexterity necessary for high-precision electronics assembly–such as meticulously winding wire around the donut-shaped core of a magnetic bobbin.

Quality…and Quantity?

While Tandon Magnetics’ female assembly workers consistently delivered top-quality results, the next issue soon arosehow could production output ramp-up to meet IBM’s rising demand as he original PC gained popularity around the world?

At a time when industrial automation in India factories was rare, Manny looked at novel alternatives to standard coil wrapping machines of the day, which were sophisticated equipment typically retailing as high as $10,000 apiece. He soon developed a relatively simple solution: adapting a household sewing machine–a pedal-operated appliance most of his female workers were already quite familiar with.

Mounting the sewing machine motor on a wooden block, he added a few enhancements, including an automatic counter to ensure the correct number of windings, as well as attaching a microscope to help the operator precisely wrap the smallest coils. After the handmade prototype proved an instant success, 100 more machines were installed throughout the assembly floor–at an estimated cost of about $5 each.

Thanks to lower overhead costs and skilled, efficient manpower–or, more exactly, womanpower– Tandon Magnetics would provide IBM with top quality PC components at volumes up to 60,000 units per day–at prices, competitors simply couldn’t match.

A Prosperous Legacy

Nearly four decades later, the early success of Tandon Magnetics has evolved into a core specialty at the Tandon Group’s Syrma Technology, providing world-class electronics design and manufacturing services to global OEMs. High-precision equipment based upon those original revamped sewing machine remains a cornerstone of Syrma’s 100,000 square foot state-of-the-art flagship facility in Chennai.